Resource Recovery Project

On average, an individual uses 130 kg of plastic a year - that's 10 ton during your entire lifetime.

My name is Mohan Jacob, Professor and Head of Electrical Engineering, and Associate Dean Research Education at James Cook University.

Resource recovery has unlimited potential. Together with my collaborator, Dr. Graham Brodie, we have customise microwave technology to convert waste into various by-products. These products can then be used in other industries, such as biochar which can be used in agriculture, ultimately contributing to a better and more circular economy.

Background and Purpose

Plastic is an indispensable material, which is cheap, versatile, lightweight, and often used as a protective layer. It has many environmental benefits especially useful for maintaining food quality, safety, and preventing waste.

On the opposite, plastic pollution has a significant negative impact on our environments, both land and ocean, and particularly affecting marine and wildlife health. Plastics endangers our marine wildlife and has also begun to enter our food chain. Although multiple countries are working to solve this issue, there is still an urgent demand for developing technologies to recover plastic waste.

Together, we have created microwave technology to decompose various wastes, mainly plastics, in small quantities, but the existing system does not offer the capacity required.

Process

The proposed crowdfunding project is aimed towards upscaling the existing treatment plant, and will be carried out in 3 stages:

- Stage 1: Developing a processing chamber, which could process different kinds of plastic materials, up to 5 kilograms of waste in a one step process. By eliminating the need to prepare the material (e.g. clean), this system will serve as a prototype for the development of biochars from different types of plastics under various conditions. The requested funding ($20,000) is to complete this stage of the project.

- Stage 2: The second stage of the project aims to optimize the energy efficiency of the system, primarily to procure a highly efficient microwave system, and reduce the power requirements. More work will be carried out to maximize the yield of by-products, and hence increase the potential for resource recovery. This stage is estimated to cost $50,000.

- Stage 3: The third stage is to build a fully customised and easy to operate Waste Processing System. It could be installed at various medium scale industries for onsite waste processing (estimated cost is $250,000) and hold a five year lifetime. The system could also be used for multiple types of waste, including mixed wastes. The successful completion of this project will have a significant impact on many industries.

Significance

The scale of plastic pollution is so vast. From the sea to the land, it is vital to develop effective interventions for the management of waste through technologies that encourage recovery of resources.

The annual plastic production is around 500 million kilograms. Although there are several initiatives aimed at solving the problem, including the collection of plastics and recycling plans, there is still plenty of mismanaged waste that ends up in our environment. Through my proposed project, plastic waste can be converted into value-added by-products and could create a better environment.

Social Media

Connect with me:

Twitter: @mohanvjacob

LinkedIn: Mohan Jacob

ResearchGate: Mohan Jacob

Google Scholar: Mohan Jacob

JCU Research Portfolio: Mohan Jacob

Budget Overview & Justification

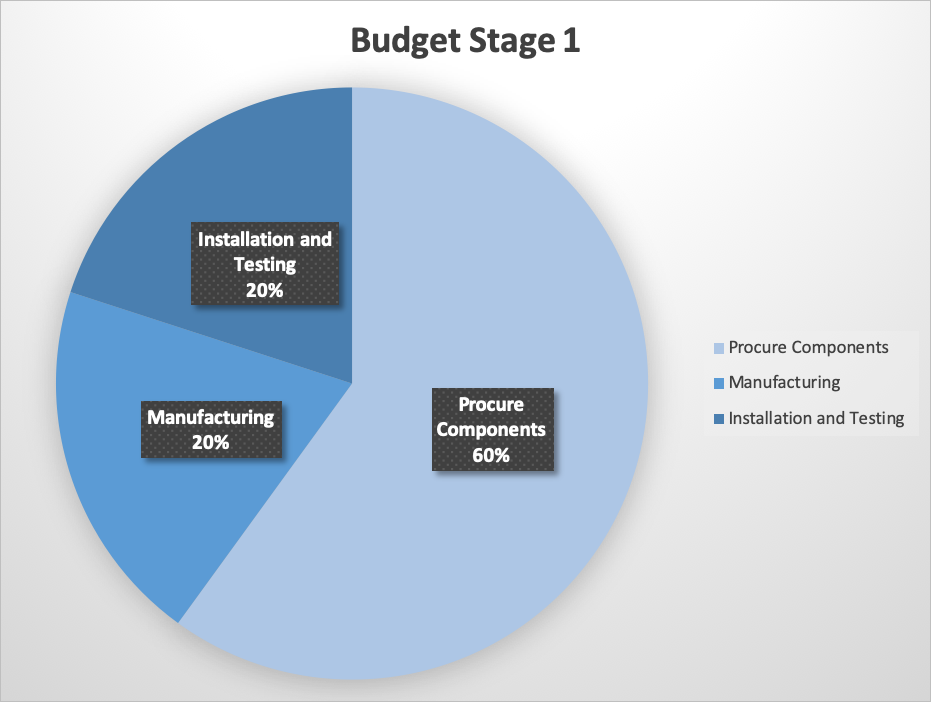

The requested funding is to complete Stage 1 of the project.

Total Requested $20,000

The project involves developing a larger processing system, and towards that, we have to source many components. Majority of the funding (60%) will be used for procurement of components required for the upgrade. We will also use a manufacturer to develop the system and incorporate the system along with the existing system. This funding is critical for initiating the Steps 2 and 3.

The project involves developing a larger processing system, and towards that, we have to source many components. Majority of the funding (60%) will be used for procurement of components required for the upgrade. We will also use a manufacturer to develop the system and incorporate the system along with the existing system. This funding is critical for initiating the Steps 2 and 3.

No reward

I just want to contribute to a better world. No reward needed.

Your name on the lab wall

Your name will be placed on the support wall in our Resource Recovery Lab to create a name cloud. The size of your name will be based on the amount of contribution: $25 gives you a medium-size version of your name. (If you wish to donate anonymously, it will display 'Thank you') Please send me your email address, I will send you a picture of the wall once completed.

BIG name on the wall in your colour

Your name will be placed on the support wall in our Resource Recovery Lab to create a name cloud. The size of your name will be based on the amount of contribution: $25 gives you a medium-size version of your name. (If you wish to donate anonymously, it will display 'Thank you') If you send me your email address, I will send you a picture of the wall once completed.

Resource Recovery lab tour

Get an exclusive insight into the research in our Resource Recovery lab with Prof Mohan Jacob. We'll arrange an Open Day for all our premium supporters at the lab on the JCU Campus in Douglas, Townsville. For every supporter who can't make it to Townsville on the day, we will take a video and send it to you. Q&A Session included